Pattern Making & Investment Casting

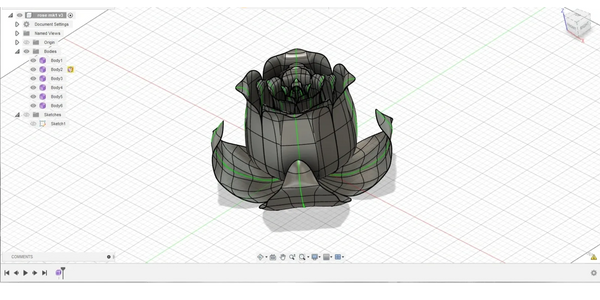

Pattern Design

At the start of any lost wax casting process is the master pattern which all following parts will derive from it is then critical that the master achieves the desired results.

Things to consider when pattern making in a foundry are shrinkage , surface finish, weight, here at G&E we still use traditional methods to make patterns but as the age of 3D printing continues its rise we also now offer 3d modeling and printing services

Mould Making

The process of making a mould can take many forms depending on the required results this may be plaster mould's were high detail is not required to cold-cure vacuum mould's which captures fine details and finally aluminium mould's for high accuracy & repeatability

Here at the foundry we have the facilities to produce vulcanized rubber mould's, cold cure vacuum mould's & aluminium mould sets

Wax Injection

Once the moulding process is complete its of to the wax injection stations where a specially formed wax is injected under pressure into the mould thus reproducing the master to the desired quantities all waxes are quality controlled before being prepared for the next process

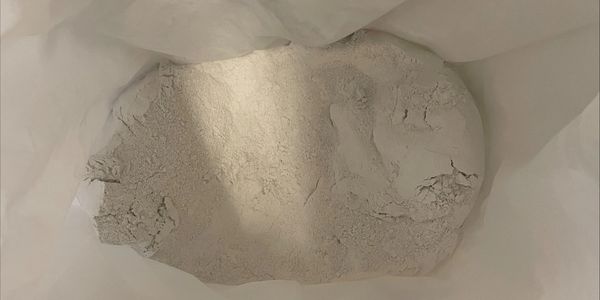

Investment Pouring

At this stage in the process its time to pour the plaster over the parts to create the flasks hence the term investment casting this involves mixing a special blend of plasters together and at the correct moment carefully pouring over the parts all this process is conducted in vacuum chambers to ensure all the detail is captured

Wax Removal

Once the plaster has set its time to remove the wax patterns from the flask to create the hollow void which is going to be filled with the desired metal this process involves steaming the flasks for a set time although this task sounds mundane it is vitally important that it is carried out correctly as any residue can have catastrophic consequences at the pouring stage

Baking

Now its time to heat treat and bake the flasks a process that requires a big oven and a sprinkle of patients this process can take anywhere up to 48hrs depending on a variety of factors it is also critical not to go to fast or too slow to avoid stressing the flasks

Melting & Pouring

With the the investment poured and the wax removed and the flasks baked we are now left with a detailed cavity which is ready to receive metal here at the foundry we melt a wide variety of none ferrous metals which are fired in single or two man crucible's these are then pored into the flasks which once again is under vacuum allowing the air to be removed and the metal to be pulled into the flask

Our Materials

Silver

Bronze + Alloys

Silver

- 999

- 925

- Britannia Silver

Gold

Bronze + Alloys

Silver

- 9k

Brass + Alloys

Bronze + Alloys

Bronze + Alloys

- Navel Brass

- SCB3

Bronze + Alloys

Bronze + Alloys

Bronze + Alloys

Nickel Silver

Nickel Silver

Nickel Silver